PNA TECHNICAL SERVICES

We are your reliable source for:

- Preventative maintenance contracts

- Screw and barrel measurements and repairs

- In-house processing and controller training

- Service contracts for general repairs and maintenance

- Material handling and equipment installations

- Auxiliary Equipment Refurbishing Services – dryer desiccant and filter replacement programs, motor and pump seal replacement, motor rewinding, granulator blade replacement

- Used equipment search, inspection and reporting services

MAKE YOUR DRYER LIKE NEW!

Try PNA Technical’s Complete Dryer Rejuvenation Program. We can work on any brand.

“PNA Technical Services completes the package of supplying value to your business.”

2024 Class Schedule

All Classes are located at the Shibaura tech center in Elk Grove, IL

Click below to Register!

January 23 – 24 – V70 Controller Training

January 25 – 26 – EC Maintenance Training

February 20 – 21 – Processing Principles

March 12 – 13 – V70 Controller Training

March 14 – 15 – EC Maintenance Training

March 19 – 21 – Molding 360

June 4 – 5 – Processing Principles

August 13 – 14 – V70 Controller Training

August 15 – 16 – EC Maintenance Training

September 17 – 19 – Molding 360

October 15 – 16 – V70 Controller Training

October 17 – 18 – EC Maintenance Training

November 12 – 13 – Processing Principles

PNA Technical Training Classes

Where: Shibaura Training Center Elk Grove Village, Illinois

Processing Principles

Processing Principles is designed for a new technician to the molding industry seeking a basic understanding of the operations of a molding machine; how to set and prepare a tool for production. The class will review the machine set up for processing the tool and emphasize how pressure and speed affect the final part. Class is taught using an all-electric injection molding press. Class is suitable for all processors – content is not specific to one press manufacturer.

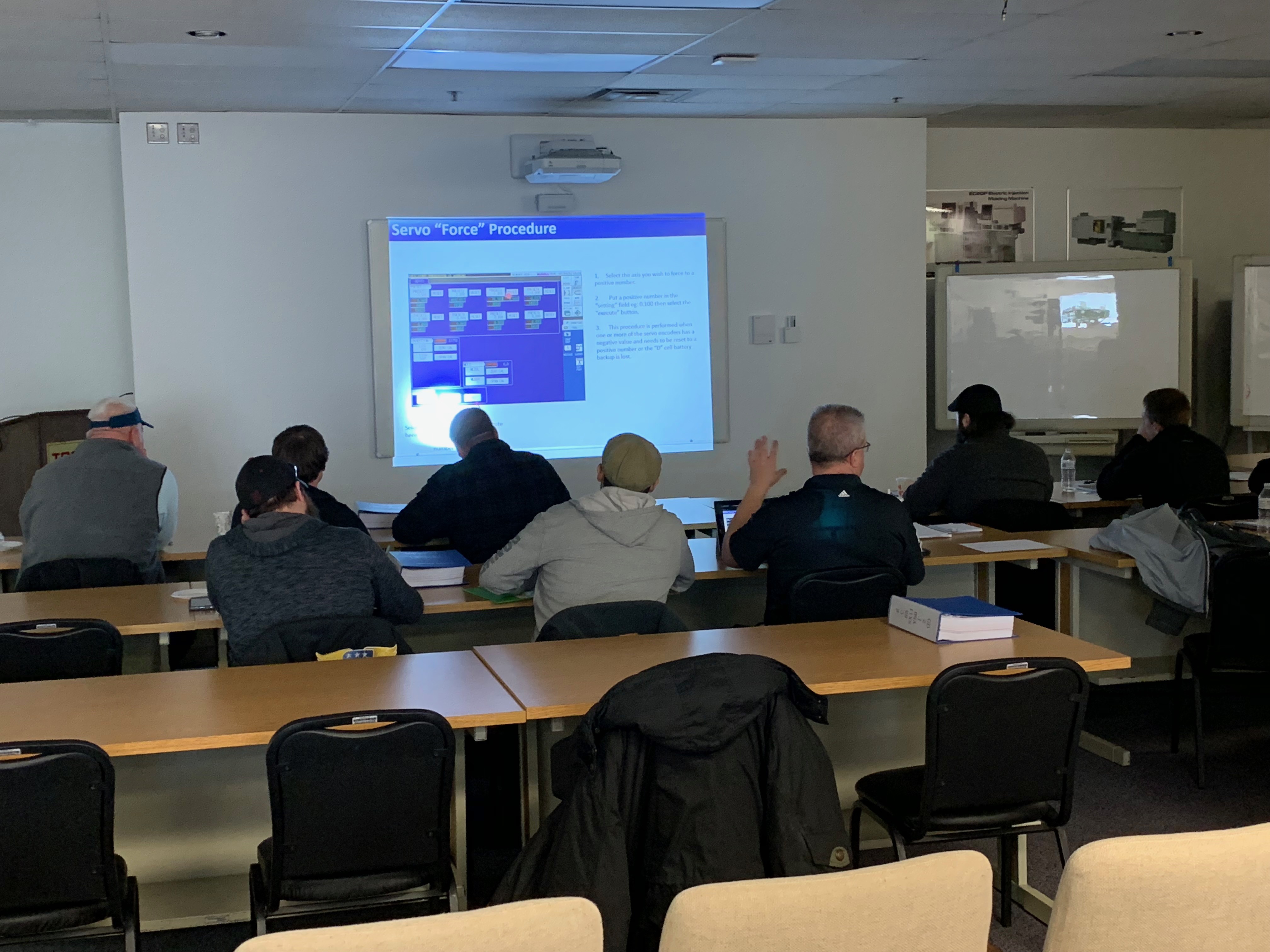

V70 Controller

The V70 classes will cover V70 enhancements as well as the features and functionalities of the V50 controller that remain consistent.

The class is designed for technicians in the molding industry who need a basic understanding of the operations of our V70 controller. In this class, students will learn the ins and outs of the controller in detail including machine capabilities, highlights of special features associated with an SX machine, and an understanding of general and sub screens.

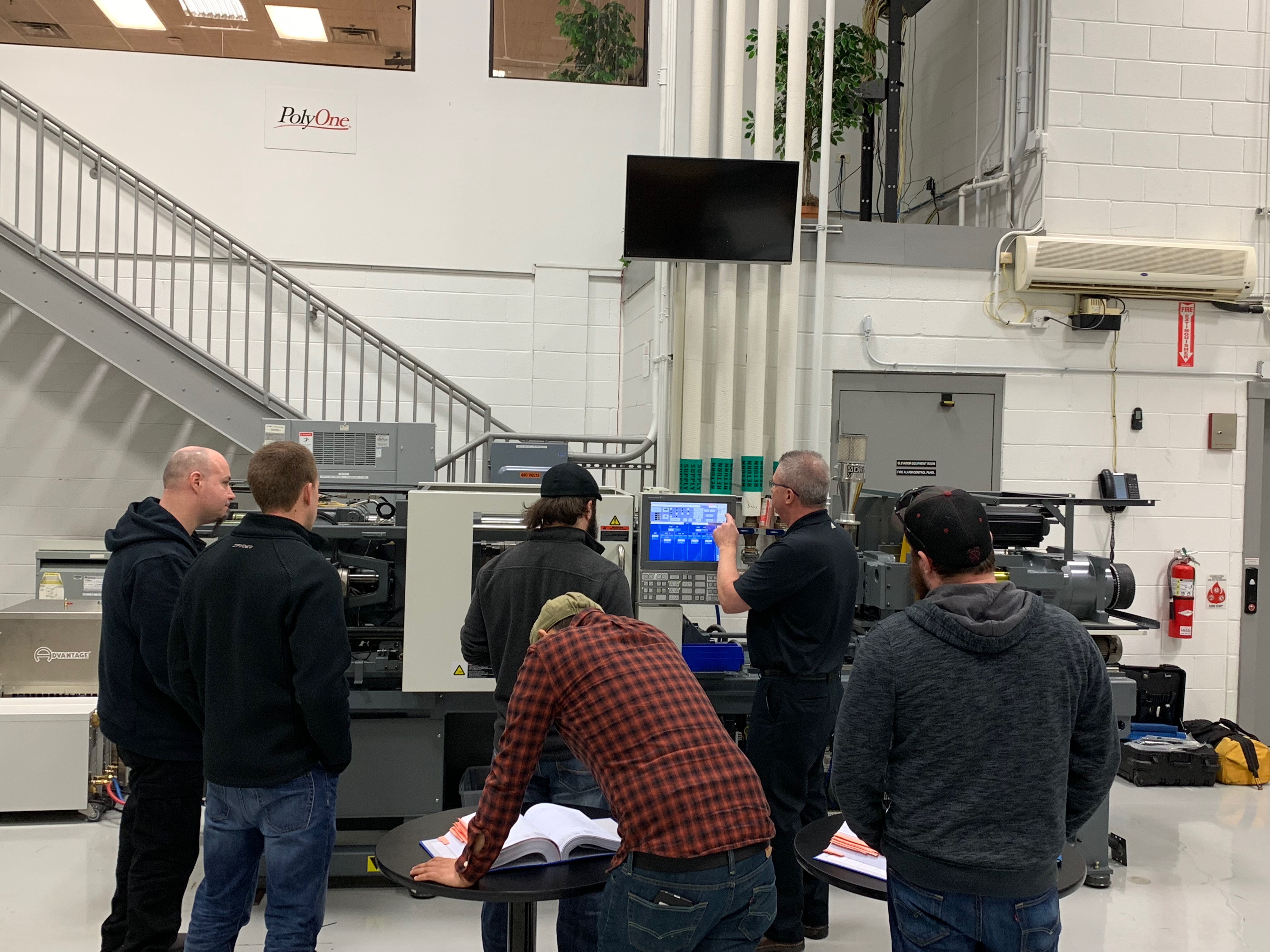

Basic EC Maintenance

The attendee must have a basic understanding of Shibaura EC All-Electric machines. Details of machine parameters, requirements for proper machine upkeep, and review of control functions will be presented. A Shibaura All-Electric machine will be used in process demonstration in conjunction with classroom training.